Style 009N - FireLock Rigid Coupling

- Angled bolt pad provides rigidity

- Sizes from 1¼ – 12″ | DN32 – DN300

- Pressures up to 365 psi | 2517 kPa | 25 bar

Style 07 - Zero-Flex Rigid Coupling

- Angled bolt pad provides rigidity

- Sizes from 1 – 12″ | DN25 – DN300

- Pressures up to 750 psi | 5171 kPa | 52 bar

Style 77 - Standard Flexible Coupling

- Cross-ribbed, two piece housing construction

- Sizes from ¾ – 24″ | DN20 – DN600

- Pressures up to 1000 psi | 6895 kPa | 69 bar

Style 75 - Flexible Coupling

- Lightweight coupling for moderate pressures

- Sizes from 1 – 8″ | DN25 – DN200

- Pressures up to 500 psi | 3447 kPa | 34 bar

Style 750 - Reducing Coupling

- Replaces two couplings and a reducing fitting

- Sizes from 2 – 10″ | DN50 – DN250

- Pressures up to 500 psi | 3447 kPa | 34 bar

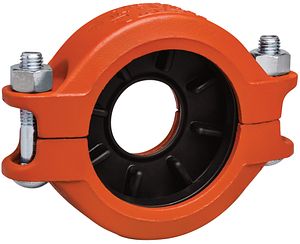

Style 741 - Flange Adapter PN10/PN16

- ANSI Class 125 and 150, Australian Standard Table E, PN10/16 and JIS 10K

- Sizes from 2 – 24″ | DN50 – DN600

- Pressures up to 300 psi | 2068 kPa | 21 bar

No. 001 - FireLock 90° Elbow

- FireLock full-flow elbows and tees feature CAD-developed, hydrodynamic design, affording a shorter center-to-end dimension than standard fittings

- Noticeable bulge allows the water to make a smoother turn to maintain similar flow characteristics as standard full flow fittings

- Fittings available from 1¼ – 12″ | DN32 – DN300

No. 003 - FireLock 45° Elbow

- 1 ¼ – 12"/DN32 – DN300

- Pressure ratings for Victaulic FireLock™ Fittings conform to the ratings of Victaulic FireLock Installation-Ready™ Style 009N couplings

- Connects pipe, provides change in direction and adapts sizes or components

No. 12 - 22 1/2° Elbow

- 45 Degrees End Type Grooved (for use with grooved couplings like Victaulic Style 07, 77, etc.)

- Ductile Iron conforming to ASTM A536 Grade 65-45-12

- Up to 500 psi / 34.5 bar (depending on system size and gasket used) 1¼" – 24" (DN32 – DN600)

No. 002 - FireLock Tee

- Ductile Iron conforming to ASTM A536, Grade 65-45-12

- 1¼" to 12" (DN32 – DN300) Up to 500 psi / 3450 kPa / 34.5 bar (varies by size and coupling used)

- -34°C to +110°C (-30°F to +230°F), depending on gasket material

No. 25 - Reducing Tee

- Main run has two equal-sized grooved ends; branch has a smaller grooved end

- Ductile Iron conforming to ASTM A536, Grade 65-45-12

- Standard: Orange enamel; Optional: Hot-dip galvanized or epoxy coating

No. 50 - Concentric Reducer

- Ductile Iron, ASTM A536, Grade 65-45-12

- Large End: 2" to 12" (DN50 to DN300) Small End: 1¼" to one size below large

- -30°F to +230°F (-34°C to +110°C) depending on gasket type

No. 51 - Eccentric Reducer

- Large and small end aligned on one side (flat bottom or top depending on flow)

- Standard: Orange enamel Optional: Galvanized or Epoxy coating

- Up to 500 psi / 34.5 bar (varies by size and coupling used)

No. 60 - Cap

- Ductile Iron conforming to ASTM A536, Grade 65-45-12

- Standard: Orange enamel Optional: Hot-dip galvanized or epoxy coated

- Up to 500 psi / 34.5 bar (varies by size and coupling)

Style 920 - Mechanical Tee BSPT

- Clamped onto existing pipe (mechanical saddle)

- 2½" to 8" (DN65 – DN200) pipe compatibility

- Ductile Iron, ASTM A536, Grade 65-45-12

Style 920 - Grooved Mechanical Tee

- Provides a direct branch connection at any location where a hole can be cut in the pipe

- Sizes from 2 – 8″ | DN50 – DN200

- Pressures up to 500 psi | 3447 kPa | 34 bar

Style 922 - Sprinkler Tee

- Provides a direct branch connection at any location where a hole can be cut in the pipe

- Sizes from 1¼ – 2½” | 25 – 76.1 mm

- Pressures up to 300 psi | 2068 kPa | 21 bar

Style 922 - IGS Sprinkler Tee

- IGS™ (Installation-Ready™ Grooved System) connection for sprinklers

- Orange enamel (standard) Optional: Hot-dip galvanized or epoxy coated

- -30°F to +230°F (-34°C to +110°C), depending on gasket

Style 920 - IGS Grooved Mechanical Tee

- -30°F to +230°F (-34°C to +110°C), based on gasket type

- Requires drilling a hole in the main pipe; installs using U-bolt clamp and gasket

- Push-to-connect with IGS outlet couplings — no threading, sealant, or tap

Style 115 OGS x IGS Reducing Coupling

- 1¼" x 1" (DN32 x DN25) and 1½" x 1" (DN40 x DN25)

- Grade “E” EPDM (Type A) Vic-Plus™ pre-lubricated gasket

- Suitable for 1" Schedule 10 and Schedule 40/STD carbon steel sprinkler pipes

Style 118 - IGS Outlet Coupling

- Ductile iron conforming to ASTM A536, Grade 65-45-12

- Grade “E” EPDM (Type A) Vic-Plus™ pre-lubricated gasket

- 1" x 1" (DN25 x DN25)

Style 912 - Sprinkler Tee

- Provides a direct branch connection for sprinklers only at any location where a hole can be cut in the pipe

- Sizes from 1 – 1½” | 25 – 40 mm

- Pressures up to 232 psi | 1600 kPa | 16 bar